Home |

Rod Making Forms |

Index Stuff Other Tools Planes Rebuilding Taper info |

| A

planing form is nothing more then a jig to hold a long thin strip

of bamboo for planing to a tapered equilateral shape. Forms

are made of various materials and in various ways. Some are

made of steel, others wood. Some are adjustable others

aren't. There are a lot of ways that forms can be

adjusted. You could hold them apart (as one person does)

with shims made of card stock. Most are adjusted by some

type of screw or bolt arrangement. Accuracy How accurate do forms have to be? Well, as accurate as you can make them. If they're out of alignment, it'll mean the 60º needed for all three sides won't be met. Can you live with 59º on one angle and 61º on the other? Probably. But two angles of 59º mean you'll have a third angle of 62º. Now you're getting into "iffy" territory. Remember, any error induced by your form will be reflected six fold when you start to glue up your strips. ( On the other hand, errors you introduce in your planing may or may not be consistent in all six strips.) |

|

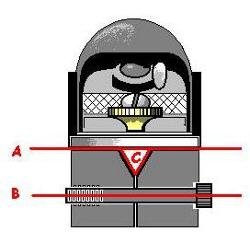

"C" is an equilateral triangle made by the two sides of the V grove and the sole of the plane. because the angle of the sole is determined by "A," the top of the planing form, "A" has to be exactly 60º to each side of the V grove. If the form is adjustable (and most forms are) then "B,"

the axis of the adjustment screw, must be parallel to "A."

Otherwise as the two sides of the form move in and out the

relation of "A" to "C" changes. The change

may or may not change the geometry of the strip to the point

it's not usable. (There are a lot of "Ifs" in this

business.) |

| The only parts of form that has

to be exact are "A," "B" and "C."

Everything else can be off by quite a bit if these three parts of

the form are correct.

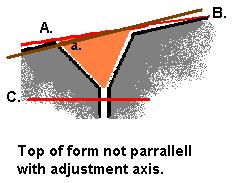

Here are the two common problems with forms. Notice that although they're similar in effect, they're caused by different problems. (The drawings are obviously not to scale, for better illustration.) |

|

In this example the top of the forms aren't

parallel with the adjustment axis ("C"). Even though the V

grove is 60º when the form are closed, an error will appear and

increase as the forms are open. The plane will ride on

points "A" and "B" changing the top edge from

the brown line (little "a") to the red line. Flipping the strip from side to side will do away with some of the error but it will be impossible to end up with a an equilateral triangle. The error increases as the forms are opened. |

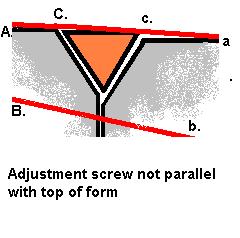

| A similar error will occur if the axis of the

adjusting screw is not parallel to the top of the form. In

the illustration, when closed all angles of the "V"

are 60º. The angle of the two sides remain 60º as the form

is open. But as the two sides separate the difference in the

angle of the adjustment screw (the line between "B" and "b")

forces one side higher than the other, inducing an error.

The line from "A" to "a" shows the error. The

plane will rest on points "C" and "a" removing material from "c." Flipping the strip will again remove some of the problem but the strip won't be right. And again the error will increase as the forms are opened. |

|

| How critical are these errors? If you can keep everything from outside to outside ( a distance of about 1 3/4in.) within .002" you'll probably be okay. But remember, if you adjust the forms outward, you'll increase the error. |

| Look at the profiles of the forms to the right. Which are okay to use and which aren't? (assuming the triangle "A" is 60º on all sides) Take a few minutes before you read the text. Think about what you're seening.

Answers... (2) Believe it or not this form will work, even though the slot (green lines) isn't square. "A," "B," and "C" line up. The slot closes completely. (3) This one will also work. Both "B's" line up with "A" and "C." The outside angles don't matter. (4) This is like no. 2. However if the gap didn't line up on the small v grove, you wouldn't be able to close the form all the way, on the tip side. (5) Oop! This will never do. The top side "B" doesn't line up with "C." The form allows the plane blade to tip from side to side. (6) This form has a real problem. Even though the two sides are parallel to "C" and are 60º to the sides of "A," they don't line up along "B." Everything's fine except for the fact that when you put your plane on these forms, it will never make the true equilateral triangle you're looking for. |

| Remember the first diagram? The things you want to line up are: 1) All three sides of your v grove should be 60º to each other. This is the most important. If you're okay there, you'll have to be really sloppy to get off far enough to be a problem. 2) The top of the form makes the top side of your triangle. Make sure it's 60º to the V grove. 3) The adjustment bolts have to be parallel to the top of the form. Everything else is icing on the cake. Forms don't have to join perfictly or be straight, or even be smooth. |

Home |

Index

Stuff Other Tools Planes Rebuilding Taper info |